Economic climate refers to acquiring probably the most Price-effective price for your procured CNC machine Software that fulfills the processing prerequisites.

For ball screws lubricated with grease, clean up the outdated grease from the screw just about every six months and exchange it with fresh new grease. Ball screws lubricated with oil should be lubricated everyday prior to the machine Resource is in use.

The numerical Management system procedures and transmits facts in the shape of Command indicators to the subsequent servo motor. The effectiveness of such Handle indicators is dependent on two essential systems: interpolation of curves and surfaces, and multi-axis movement Charge of the machine Resource.

We now have an extremely professional and committed community of distributors who characterize Hurco through North The united states, and we hope the Hurco Hook up Web site can be employed to complement the help they provide their customers. You will find Call information and facts for the distributor at this backlink: Distributor Locator

The vertical machining center In most cases has three linear movement coordinates. Worktable is connected with a horizontal axis rotary desk. This helps it to fabricate round Workpieces with no issue.

Education and Allocation: Right schooling ought to be presented to operators, routine maintenance staff, and programmers to be certain Safe and sound and productive use of the CNC machine Software.

Now, numerical Handle machine tools have lots of pros more than conventional machine tools and are being commonly used in the machining business.

Feed price refers back to the velocity at which the cutting tool operates along the workpiece throughout its solitary rotation.

Download CNC machines are fashionable subtractive manufacturing equipment, which quickly Management the Instrument route and motion for content removing.

The geometry of the tool frequently influences the cutting technical specs and effects. The horizontal machining centers are shorter and thicker, which suggests they may have the stability required to maintain resistance even though machining deeper cuts.

Headstock holds and centers the function for accurate positioning and alignment, it encloses the machine spindle and powdered it.

When making use of simulation software for processing, Visit this page it’s essential to carefully enter all parameters to avoid careless problems that may bring about incorrect simulation processing and potential collisions all through precise processing, resulting in squandered parts.

They also needs to concentrate on the position and way of applicable sections inside the machine Software all through distinct processes.

Exciting information from RapidDirect! We’ve rolled out two interesting updates to enhance your manufacturing journey.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Mr. T Then & Now!

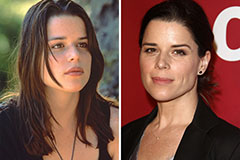

Mr. T Then & Now! Neve Campbell Then & Now!

Neve Campbell Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!